Safety First: Ensuring Safety and Compliance in Facility Maintenance

October 17, 2025

You know that conference room, the one where you’re explaining how a tech’s five-minute shortcut landed someone in the ER and turned into a six-figure insurance claim. Upper management wants answers. Legal’s taking notes. Everyone’s suddenly very interested in your facility maintenance program.

The tech skipped the lockout procedure because he’d done the same repair a hundred times. The schedule was packed, the part was back-ordered, and nobody thought this one would be different. Except it was.

Here’s the pattern: Facility maintenance runs like a to-do list that never gets shorter. Teams jump from emergency to emergency. Work orders pile up. Safety protocols get flexible when deadlines get tight. Then something breaks. Or worse, someone breaks.

Some facilities, though, have figured out a better way. And that’s what we’re walking through here.

Start Where the Lawyers Will Look First

The calls always come at the worst possible time. Someone slipped, something broke, or an inspector showed up with a clipboard and a bad attitude.

Here’s the thing: Your building tells you what’s about to go wrong long before it actually does.

Walk your sites like a plaintiff’s attorney preparing a case against you. Hit the parking lots, entrances, and stairwells first — anywhere people rush through without paying attention. Document every crack, dark corner, and puddle that appears after it rains, and plan ahead — because these aren’t maintenance issues anymore, they’re future depositions.

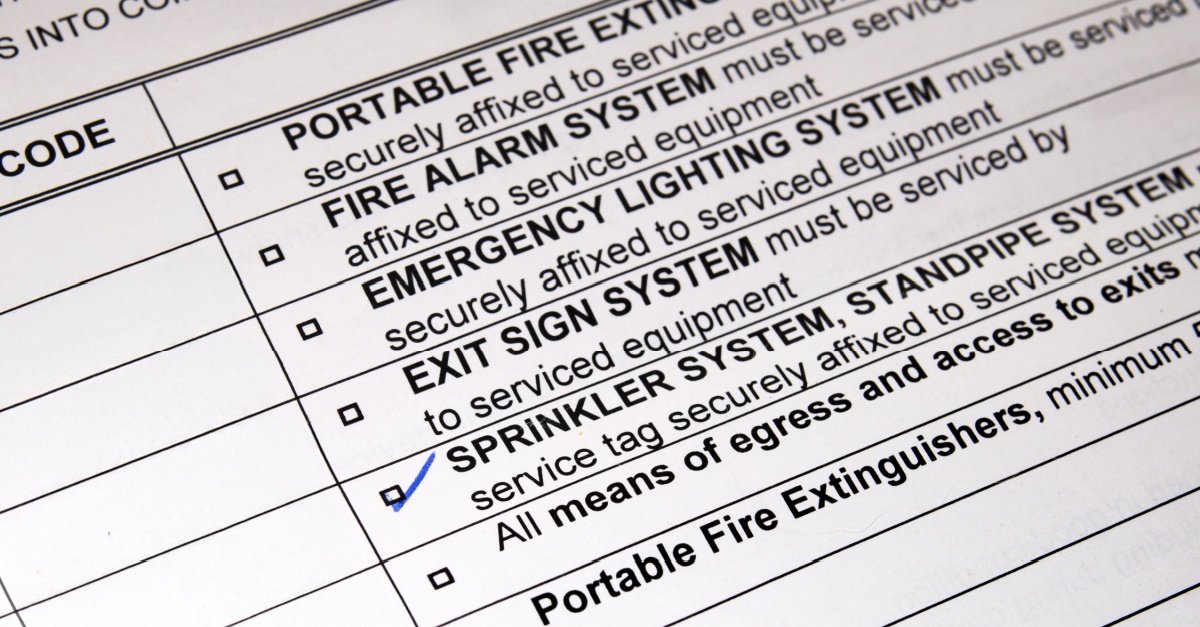

While you’re at it, catalog everything mechanical that keeps your building breathing. HVAC units, generators, fire systems — age, condition, last service date. You’ll need these facts when things go sideways, and things always go sideways eventually.

Pull three years of inspection reports too. If you see the same violation showing up over and over, your maintenance program has a blind spot, and inspectors already know exactly where to find it.

Build a Schedule That Stops Problems Before They Start

You’ve identified the problems. Now build a facility maintenance schedule that fixes them before they blow up.

Start with anything that keeps people safe and regulators check first. Think ADA ramps, handrails, and emergency exits that need to stay clear and lit.

Then, make sure your maintenance calendar matches the regulators’ inspection calendar. NFPA wants quarterly sprinkler tests? Schedule them for the first week of each quarter. OSHA requires annual lockout/tagout reviews? Pick a month and stick to it. Missing these deadlines costs more than doing the work twice.

Deadlines also mean nothing without names attached. Assign every single task to a specific person or vendor with a real due date. Quarterly HVAC tune-ups, monthly generator tests, and filter changes. Someone quits, and your entire schedule collapses if nobody owns each piece.

Most importantly, budget for all of it upfront. Planned facility maintenance costs 12-18% less than waiting for things to break. Pay now or pay triple when the HVAC dies during a heat wave and you’re calling emergency vendors.

Track Everything or Track Nothing

Good intentions mean nothing without good records. Your team might complete every task perfectly, but if you can’t prove it when the inspector arrives, you’re toast.

CMMS software is a good place to start. It schedules tasks, sends reminders, and stores every inspection report where you can actually find it later. Instead of digging through filing cabinets or calling the tech who quit last year to ask where they kept their paperwork, you can pull up whatever you need in seconds.

Smart sensors make tracking even easier. They catch temperature spikes, unusual vibrations, and moisture problems before equipment fails completely. Your techs get alerts on their phones and fix small problems before they become big ones.

Mobile apps also let your team upload photos and signatures from the field. Geo-tagged, time-stamped proof that beats “trust me, I checked it” every time.

Train Employees and Cultivate a Safety Culture

Software tracks tasks, but people still do the work. They need to know exactly how to stay safe with your specific equipment and chemicals.

Make training practical and frequent. Show new hires the actual lockout procedures for the machines they’ll touch. Review emergency responses for the building they work in daily. Run refreshers quarterly because everyone develops bad habits.

Test what they learned with surprise drills. Fire evacuations, chemical spills, equipment failures. Better to catch mistakes during practice than during the real thing.

You want to create a culture where reporting problems beats hiding them. Make it easy and blame-free. Someone spots a frayed wire? They report it immediately without fear of getting written up for not catching it sooner.

Most importantly, leadership sets the tone. Your team will skip the same steps you skip and follow the same procedures you follow.

Audit Performance and Continuously Improve

Your safety program needs regular checkups to stay effective. Training gets everyone started, but without audits, people drift back to old habits and dangerous shortcuts. Rotate your inspection teams. The same person checking the same areas every week goes blind to problems — they walk past that extension cord stretched across the loading dock so often they don’t see it anymore. Fresh inspectors spot hazards immediately because everything looks new to them.

Track recurring problems to find system failures. When three people slip on the same wet floor, you don’t need another warning sign. You need better drainage. Repeated incidents reveal broken processes that need fixing at the source.

Update procedures when your facility changes too. Every renovation, new piece of equipment, and layout adjustment makes your old safety protocols obsolete. Who knows? Maybe that evacuation route you mapped two years ago might lead straight into a wall now.

Your Facilities Deserve Better Than Emergency Mode

Facility maintenance boils down to a simple choice: Fix problems on your schedule or fix them on theirs — “theirs” being the inspector who just failed your sprinkler system, the employee who just slipped in your parking lot, or the HVAC unit that picked the hottest day of summer to die. Following the framework we’ve outlined here turns your facility maintenance from reactive panic into a predictable routine — one where you catch problems while they’re still small, cheap, and nobody’s calling their insurance company about them.

At BrandPoint Services, we don’t believe that facility executives managing multiple locations should have to coordinate 20 different contractors who might show up. We’re your single point of contact for maintenance across all your sites, whether you run retail stores, bank branches, or healthcare facilities. Our team audits your current maintenance state, develops a real plan with real deadlines, schedules the work, and manages every contractor to completion.

If you want to see what facility maintenance looks like when someone else sweats the details, connect with BrandPoint Services today and let’s talk about taking your facilities out of emergency mode for good.