Scaling Smart: How to Handle Facility Maintenance for Multi-Site Operations

November 12, 2024

Expansion requires an investment in facilities maintenance if brand consistency and operational efficiency across multiple sites is the goal. However, managing facilities maintenance for multi-site operations comes with unique challenges. Businesses face difficulty coordinating resources across locations, each with its own specific needs, from equipment to climate variations. Balancing the resources required to keep each site running smoothly is no small task, and maintaining consistency in service quality across all locations requires disparate vendors and staff to abide by central guidelines.

Prioritizing streamlined, proactive maintenance reduces unexpected expenses and ensures smooth operations, ultimately supporting brand integrity and customer satisfaction across the board. These six smart scaling strategies will help you make sure all of your facilities are at their best.

The Challenges of Multi-Site Facility Maintenance

Multi-site facility maintenance faces challenges like managing diverse needs, where each location has unique requirements and regulations, and vendor variability, which can affect service quality. Communication gaps between sites and central management, cost control difficulties, and limited real-time data visibility further complicate proactive issue identification and cost management. These challenges can make managing multiple sites untenable, making smart scaling strategies the key to effectively managing multiple facilities.

Smart Scaling Strategies for Multi-Site Facility Maintenance

To curb the deleterious effects of miscommunication, inconsistent vendor quality, and unexpected equipment failure, it’s best to establish as much control as possible by implementing industry-proven strategies that prioritize data-driven decision-making and centralized operations.

1. Centralized Facility Management System

A centralized facility management system (CFMS) can put all your locations at your fingertips by unifying all of them, their schedules, and tasks on a real-time platform. The setup enables managers to monitor performance consistently across sites, automate work orders, and schedule preventive maintenance, minimizing overlooked tasks and costly reactive repairs related to facility maintenance. For instance, a retail chain can use CFMS to oversee HVAC systems across stores from a single dashboard. If an issue arises, CFMS auto-generates a work order, assigns it to the closest technician, and ensures quick response, saving energy and reducing downtime while supporting sustainable growth.

2. Standardizing Maintenance Protocols Across Sites

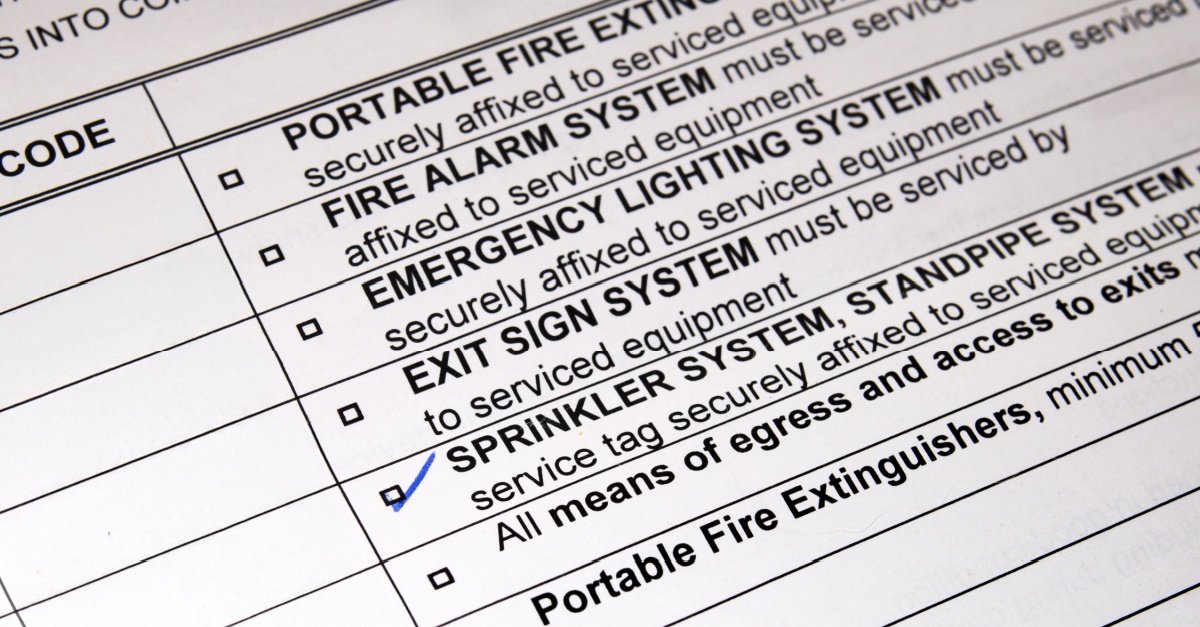

Consistency and reliability are essential for building customer trust and loyalty across multiple locations. Standardized facility maintenance protocols are integral to achieving that customer connection. You must establish clear quality benchmarks and develop detailed checklists for inspections, repairs, and preventive tasks, ensuring uniformity and minimizing oversights. Regular audits and feedback loops reinforce adherence, creating a robust framework for quality control and operational excellence. This structured approach keeps facilities maintenance standards top-of-mind for all staff, ensuring consistent performance across locations and preventing weak links in operations.

3. Vendor Consolidation and Management

Vendor consolidation is key to ensuring consistent quality across multiple sites. Relying on different vendors risks incompatible maintenance standards, leading to uneven service. Partnering with a single, reliable regional or national provider familiar with your standards minimizes service variability, ensuring all sites meet consistent criteria. Consolidation also enables companies to leverage economies of scale for favorable contract terms, reducing costs while boosting consistency. Instead of managing varied vendors and rates, this cohesive approach simplifies operations and strengthens vendor relationships, benefiting every location equally.

4. Leveraging Data and Analytics

Multi-site facilities maintenance becomes highly effective by leveraging data from IoT devices and sensors. These tools enable real-time monitoring of equipment health and energy usage, giving facility managers immediate insights into each location’s operations. By analyzing this data, teams can optimize maintenance schedules, predict potential equipment failures before they happen, and increase efficiency. For example, IoT sensors can track HVAC performance across all sites, identifying early signs of wear to prevent costly repairs. This data-driven approach not only reduces downtime but also enhances operational consistency across facilities, creating a proactive and efficient maintenance strategy while also potentially reducing energy costs by 10-20%. In modern facilities maintenance, multi-site management without a data-driven approach is a disservice to your customers.

5. Flexible and Scalable Staffing

Multi-site facilities maintenance means different locations can experience different issues, requiring flexibility with your maintenance strategy, including the types of workers you staff. By aligning personnel to real-time needs, this model ensures skilled staff are available where and when required, adapting efficiently to fluctuating demands across locations. Outsourcing non-core functions, such as janitorial services, helps reduce internal overhead, allowing in-house teams to concentrate on critical maintenance tasks. Partnering with specialized vendors for outsourced roles supports consistent service quality, reduces operational costs, and frees up resources for strategic priorities. This approach creates a responsive staffing solution that boosts efficiency and maintains high standards across all sites.

6. Developing a Preventative Maintenance Schedule

A preventative maintenance schedule is essential for multi-site facilities to keep everything running smoothly. A sudden equipment breakdown during peak hours can be costly and disrupt operations. Regularly scheduled maintenance helps prevent these surprises, ensuring each piece of equipment operates reliably. But a one-size-fits-all approach doesn’t work; each location’s needs vary. For instance, equipment in a high-traffic area might need more frequent servicing than in a quieter spot. Tailoring the schedule by equipment type, usage, and site-specific conditions allows managers to maintain uptime and optimize resources, making operations smoother across all locations.

The Benefits of Scaling Smart

Once you’ve integrated these smart scaling strategies into your facilities maintenance, you’ll be able to ensure consistent facility experience for every customer at all locations, reduced downtime from unexpected equipment issues, and a more cost-friendly relationship with your vendors that’ll streamline your entire operation.

Cost Efficiency

Consolidating vendors and streamlining maintenance processes reduce operational costs by creating efficiency and lowering service variability across sites. In the past few years, more than 60% of large enterprise companies have consolidated vendors, citing cost reduction and operational efficiencies. Facilities that consolidate vendors report 10-20% savings by reducing the number of vendors used and minimizing redundant service fees.

Moreover, preventative maintenance reduces unplanned repairs by identifying issues early, extending equipment life, and reducing downtime by 35-45%. Fewer reactive repairs not only cut down on costly emergency services but also enhance energy efficiency. Well-maintained equipment operates at optimal performance, can lower energy costs, and provides sustainable, long-term cost control across facilities.

Improved Consistency Across Sites

Facilities achieve improved consistency across multiple sites by implementing standardized protocols and centralized management, ensuring each location delivers high-quality service. With centralized control, brand standards are easily enforced, resulting in increased operational efficiency due to reduced variability across sites. This uniformity in service quality strengthens the brand experience and boosts customer satisfaction, as clients enjoy a reliable, consistent experience at any location they visit. Companies have experienced a 15% increase in revenue, partly due to return customers. Additionally, centralized facilities management improves resource allocation, further supporting consistency and reducing downtime by 25-30% through proactive, standardized maintenance processes.

Increased Operational Efficiency

Operations can run smoother when advanced technologies act as invisible workers checking every piece of equipment at all times. With real-time data and analytics, facility managers can receive instant alerts if a machine’s performance dips, like when a pump’s temperature spikes unexpectedly. This proactive insight allows them to address minor issues early, preventing major breakdowns. Automated processes further ease their workload by automatically generating work orders and setting up maintenance schedules. As a result, they can focus on strategic planning rather than daily troubleshooting, creating a smoother, more efficient operation and significantly reducing the chances of costly, unexpected repairs.

Enhanced Predictive Maintenance

Getting ahead of problems will always be one of the best ways to ensure all facility locations run optimally. Predictive maintenance tools significantly reduce unexpected downtime by identifying early signs of potential equipment failures. If an HVAC system in one location is consuming more energy than normal without having a higher cooling output, the IoT sensors attached to it can alert the maintenance team for a quick fix instead of letting the equipment deteriorate. Predictive maintenance can cut downtime by 20% on average, allowing facilities to proactively address issues before they lead to costly breakdowns. Using IoT sensors and advanced data analytics, predictive maintenance provides real-time insights, reducing the likelihood of unexpected disruptions so you can continue to service the customers that make your company great.

Better Vendor Relationships

Better vendor relationships are a game-changer for multi-site facilities maintenance. Imagine working with a few dependable vendors who know each site’s unique needs and are invested in keeping things running smoothly. Fewer vendors mean stronger partnerships, where trust grows over time, leading to better contract terms—like priority service or volume discounts. These reliable partners are quicker to respond and more likely to go the extra mile because they understand the facilities inside out. With fewer moving parts, maintenance becomes smoother, more predictable, and ultimately more cost-effective, creating a stable, streamlined operation across all locations.

Scale Smarter With A Multi-Site Facility Maintenance Partner You Can Trust

Facility maintenance across multiple sites requires proper understanding that miscommunication, inconsistent maintenance quality across multiple vendors, and fluctuating costs due to repairs and vendor relationships are deterrents to smartly scaling your business. Luckily, your operation can be cost-efficient by consolidating vendors, having consistent maintenance quality across sites by standardizing maintenance protocols, and being streamlined by leveraging data to stay ahead of equipment failure and centralizing all maintenance activities in one platform.

BrandPoint Services are trusted experts in all of that and more. We can simplify your vendor management by being your single point of contact for everything from monitoring equipment across multiple sites with IoT devices to leveraging our centralized dispatch system to deploy our national network of trusted technicians to ensure all your facilities meet your quality standards. BrandPoint is proud to work for over one-third of the nation’s largest multi-site companies. It’s time to talk to an expert if you’re ready to scale your business confidently.