When Seasons Change: How to Manage Seasonal Maintenance Tasks Efficiently

September 29, 2025

You manage facilities long enough, you learn one truth: Seasonal maintenance either runs you or you run it.

Every VP and director knows that feeling when October rolls around and you realize the boiler inspections got pushed back again, or when April hits and half your rooftop units need service yesterday.

The difference between facilities teams that play catch-up and those that stay ahead comes down to systematic planning. Seasonal maintenance done right means your equipment runs longer, your repair budgets stay intact, and you stop fielding those early morning emergency calls.

In this seven-step framework, we walk you through building an efficient seasonal maintenance plan: from auditing needs to leveraging technology, coordinating teams, and integrating emergency readiness.

Step 1: Assess Seasonal Risks and Priorities (Anticipation)

Start your seasonal maintenance plan where problems actually live: your building’s weak spots.

Pull last year’s work orders and patterns jump out immediately. HVAC units crashed during heat waves, roof drains clogged with fall leaves, boilers wheezed through February, and so on. These failures map directly to what needs attention before each season hits.

Your building management system holds the road map. Temperature logs reveal when cooling towers start straining, while pressure readings catch boiler issues weeks before they escalate. And if your facilities team is intelligent, you’ll monitor these metrics year-round. That’s the best way to turn data patterns into maintenance schedules that prevent seasonal surprises.

Then, rank everything by business impact and focus efforts where downtime hurts most. For instance, one chiller failure during peak summer costs more than 10 minor repairs combined, so critical systems that keep operations running get priority. Match your seasonal maintenance intensity to business impact and protect what matters most.

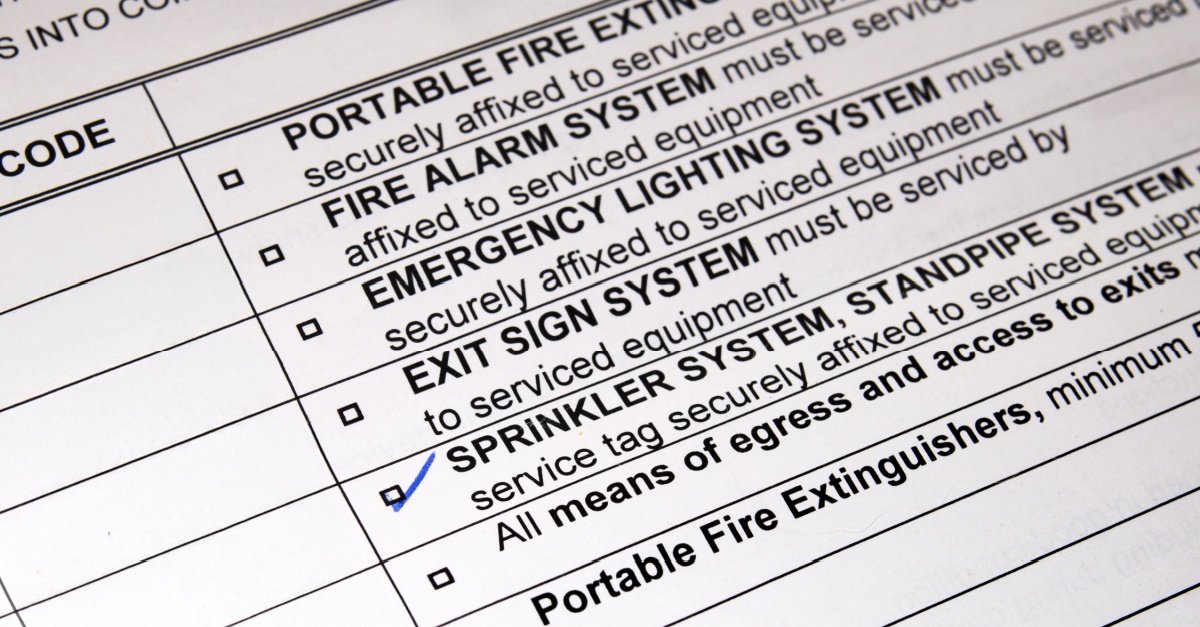

Step 2: Build Comprehensive Seasonal Checklists and Plans

Those vulnerability patterns you’ve just identified aren’t simple data points — they’re your blueprint for action. Generic maintenance templates might work for generic buildings, but your facilities have their own unique personalities and pain points that demand a more thoughtful approach.

Consider how your historical data can shape proactive care. Those HVAC systems that failed during last summer’s heat wave and the roof leaks that appear like clockwork every March are practically begging for preseason inspections. When you build checklists that speak directly to your buildings’ documented weaknesses, you’re both maintaining and preventing.

Vague instructions, though, lead to incomplete work. “Check HVAC” should be something specific and executable like: “Replace filters, test refrigerant levels, and calibrate thermostats on all rooftop units by April 15.” Every task should trace back to a specific risk you’ve identified and create a clear line between past problems and future prevention.

Remember, you’re not writing these plans for yourself — you’re creating them for the technicians who’ll bring them to life. Clear instructions paired with specific deadlines and assigned responsibilities turn well-meaning intentions into completed work orders.

Step 3: Allocate Resources and Schedule Efficiently

Perfect checklists still fail without people and parts to execute them. Every task you just documented needs resources locked in months ahead — HVAC filters ordered before suppliers run out, snow removal crews contracted before everyone else grabs them, landscape vendors scheduled while their calendars remain open.

Seasonal maintenance fails when parts arrive late or vendors book up.

In other words, timing drives everything. Schedule HVAC startups weeks before heat waves arrive, not after complaints start rolling in. Block calendar windows that respect both weather patterns and business operations — your April rooftop inspection might shift a week for rain, but you’ve already built that buffer. Smart scheduling means working around your facility’s rhythm, not against it.

If you’re managing multiple sites, you have even more variables to consider. The most important thing you can do is to stagger your seasonal maintenance geographically to prevent vendor bottlenecks, spread costs evenly, and keep your teams from drowning during seasonal transitions. Northeast properties winterize first, Southeast locations can wait weeks longer, for instance.

Step 4: Leverage Technology and Automation

Manual coordination of all these moving parts eats up the time you don’t have. So, embrace a CMMS to automate your seasonal maintenance. Very quickly, those checklists you built become recurring work orders that generate themselves, notify technicians automatically, and track completion without constant oversight. Set it once, and April HVAC inspections appear every year like clockwork.

Sensors take automation further. Compressor runtime data triggers refrigerant checks before problems develop. Temperature anomalies flag HVAC issues weeks before occupants complain. Real-time monitoring feeds directly into your CMMS, adjusting seasonal schedules based on actual equipment performance rather than calendar guesses.

When surprises hit — and they will — adaptive scheduling tools keep everything on track. Sick technician? Emergency repair? Drag and drop tasks to available crews while maintaining visibility on your seasonal maintenance progress. Dashboard views show exactly what’s complete, what’s pending, and what needs immediate attention.

Step 5: Embrace Preventive (Not Reactive) Maintenance

All that automation and data mean nothing if you’re still chasing breakdowns. The whole point of seasonal maintenance shifts your team from firefighting to fire prevention, because every facilities leader knows the painful truth: Emergency repairs cost three to nine times more than planned work.

That’s budget money burning because you waited too long.

Target tasks that deliver maximum protection. Cleaning HVAC coils and replacing worn belts improves efficiency by 40% while preventing those mid-summer meltdowns. Fall drainage inspections stop winter water damage before it starts. And so on.

Track everything and document what you find during seasonal maintenance rounds too. That strange vibration in Unit 3, the seal wearing faster than expected, the filter that needs changing monthly instead of quarterly. These discoveries shape next year’s plan and prove you’re managing assets, not just reacting to failures.

Step 6: Communicate and Coordinate Proactively

Your best seasonal maintenance plan fails when nobody knows it exists. The technicians running inspections, tenants working through service windows, and vendors providing support all need to understand what’s happening and why. Give them advance notice before that HVAC shutdown or parking lot closure, and that disruption becomes a scheduled improvement that everyone expects.

That said, communication is a two-way street. Your frontline techs see problems brewing that never make it into reports. So, bring them into planning sessions and listen. They’ll spot gaps in your checklists and fix scheduling conflicts before they happen. When people help build the seasonal maintenance plan, they actually follow it.

The same principle applies to vendors. The best contractors fill their calendars early, so waiting until you need them guarantees you’ll get whoever’s left. Establish relationships, lock in rates, and coordinate schedules while you have leverage. Then use your CMMS to keep everyone aligned — internal teams and external vendors watching the same dashboard, catching delays before small slips become major problems.

Step 7: Integrate Risk Planning and Continuous Improvement

Even perfect coordination can’t stop extreme weather from testing your systems. That’s why smart facilities leaders treat seasonal maintenance and emergency preparedness as one unified strategy. While your team inspects the HVAC each fall, they’re also testing backup generators for winter outages. During spring roof checks, they’re confirming sump pumps can handle sudden downpours. Every routine task doubles as disaster prep.

Yet, preparation without testing is just wishful thinking. Load test those generators under real conditions. Run fire pumps at peak summer demand. Simulate flooding scenarios before storms arrive. Your seasonal maintenance proves itself when stressed, not when everything runs smoothly.

Then, after each season, audit what actually happened. Which predictions missed? What took longer than planned? Where did budgets break? Feed these lessons back into next year’s plan. Over time, this cycle of seasonal maintenance, testing, and refinement will build a system that handles whatever the weather throws at you.

Time to Make Weather Work for You

Seven steps might sound like a lot, but they all build on one reality: seasonal maintenance either controls you or you control it. You’ve seen how the pieces connect, how each step feeds the next, and how each ingredient creates a system where spring’s lessons improve fall’s execution, where this year’s data makes next year smoother. The facilities leaders who master this aren’t lucky. They’ve just figured out that seasonal transitions follow patterns, and these are patterns you can plan for.

BrandPoint Services exists because even the best seasonal maintenance plan needs flawless execution. We’ve spent years building a contractor network that covers every trade and every region, all coordinated through account teams who learn your facilities like they’re our own. When April rolls around and those HVAC tune-ups need to happen, they happen. When November brings the first freeze warnings, your systems are already winterized. We handle the vendor management, the scheduling complexity, and the quality control, so you don’t have to — all as one provider with many solutions

Connect with BrandPoint Services today and discover what seasonal maintenance feels like when someone else sweats the details.